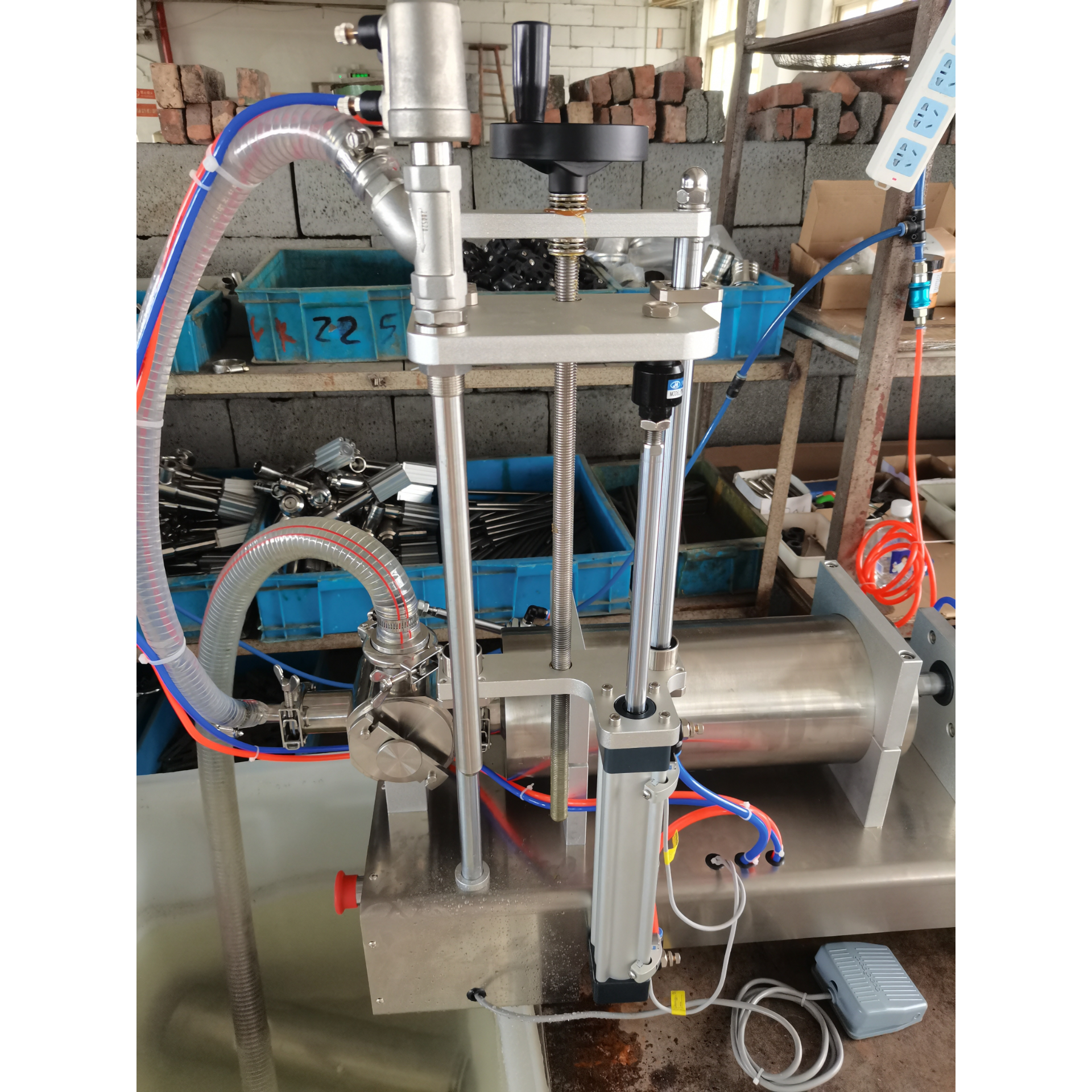

Filling – Bottom Up Filling System

A bottom-up filling system is a method of filling containers with liquid or powder products. In this system, the product is introduced into the container from the bottom up, rather than from the top down. This method is particularly useful for products that tend to foam or splash when poured from a height.

Benefits of bottom-up filling systems:

Reduced foaming: By introducing the product from the bottom, air is not whipped into the liquid, which helps to minimize foaming. This is important for products such as detergents, shampoos, and milk.

Reduced splashing: The slow, gentle introduction of the product from the bottom helps to prevent splashing and spills. This is important for products that are expensive or hazardous to spill.

Improved accuracy: Bottom-up filling systems can be very accurate, as the product is dispensed directly into the bottom of the container. This is important for products that must be filled to a precise level.